Joint Tenancy vs Tenancy in Common

The same principle applies to Capital Gains Tax purposes – gains are split equally for those who own as joint tenants and in accordance with each owner’s share. Under these statutes, the persons who are to receive the property on the death of the original owner may be designated as beneficiaries for accounts in financial institutions, securities, real estate and other instruments of title. Thus, on the death of one co-owner, his or her interest will not pass to the surviving owner or owners but will pass as an individual share according to his or her will or, if there is no will, by the law determining heirs.

Tenants in Common vs Joint Tenants

Or you and another person can own property as tenants in common. When a non-spouse is added to the title of property as a Joint Tenant, the government deems it to be a gift. Unfortunately, the government takes a dim view of these transactions, sometimes considering them to be gifts, not estate planning strategies.

Which is Better: Joint Tenants or Tenants in Common?

If the premises are rented to a non-owner, all co-tenants would be entitled to share in the rent. Any co-tenant has the right to live in the premises without paying rent to the other owners, and every co-tenant may be entitled to credits for items such as taxes, maintenance and repairs. This will ensure that you are fully aware of the legal implications of your decisions and can decide which ownership structure works best for you. Ultimately, it’s up to you and your partner to decide which ownership structure works best for you. The difference between joint and tenancy in common doesn’t usually carry any tax implications when you buy the property, assuming it is to be your home and not an investment property. A solicitor can help you choose the ownership that makes sense for you and your family.

Who pays taxes on a joint tenant account?

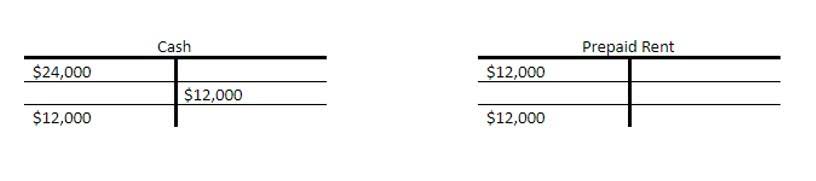

Taxes on a joint account are typically split between co-owners of the account. However, that doesn't necessarily mean the responsibilities—and workload—will be divided evenly between parties.

Quicken WillMaker & Trust by Nolo

- When Janice dies a few years later, the property will form part of her estate.

- Under Minnesota law, when a deed does not specify whether the property is being purchased as tenants in common or as joint tenants, the law presumes the owners to be tenants in common.

- I am very grateful to Mr. Jules Martin Haas attorney of law in New York.

- For instance, you can own property solely in your own name.

- The Klun Law Firm serves clients throughout Minnesota and out-of-state clients with real property in Minnesota.

Transferring property into joint tenancy may also result in a gift tax. If all the property owned at death – including joint property, life insurance and employee benefits – exceeds a certain exemption limit, the estate may be subject to federal and state estate taxes. Creating a joint tenancy with someone other than your spouse may result in a gift being subject to gift tax. Except for joint bank accounts, it cannot be revoked or reversed without the joint tenant’s cooperation, and for real property the cooperation of the joint tenant’s spouse is also required.

For instance, if you bought rental property for $125,000 and sell it later for $200,000, you would owe capital gains taxes on $75,000. In these states, using Joint Tenancy can actually expose your estate to costly capital gains taxes. However, almost half the states have a separate state estate or inheritance tax which kicks in at a much lower level.

What does “joint tenants with the right of survivorship” (JTWROS) mean?

If the ownership share goes to the deceased’s spouse or civil partner, no tax is due on that transfer, regardless of whether they are owned as joint tenants or tenants in common. Structuring your ownership of property as a joint tenancy can be an important part of your estate planning process because it can be an effective tool to transfer assets outside of probate. If you want to create a joint tenancy or take possession of property as joint tenants, make sure that your lawyer or real estate agent is very careful about the phrasing in the deed or will. If you own property and your ownership is structured as joint tenancy, New York law may permit the transfer of the property outside of the probate process after one of the owners passes away. Should one of the owners die, their share in the property automatically transfers to the other joint tenants.

Alternative to the right of survivorship

In this case, Peter’s children would have been able to inherit a share of the family home. When Janice dies a few years later, the property will form part of her estate. Peter could not leave his share of the home to his children from a previous relationship. Each owner receives a percentage of the sale proceeds when the property is sold.

Control exactly how your estate is distributed — including who your beneficiaries will be, when they will receive your legacy and how they will receive it. For instance, you can own property solely in your own name. Whether your Joint Tenant is your spouse or someone else, the implications of this exposure to loss are frightening. That means you effectively lose control of half the property.

Why avoid joint ownership?

Problems With Joint Ownership

In addition to failing to avoid probate, joint ownership can great other problems during a lifetime. By jointly owning property, you may find yourself party to a lawsuit if your co-owner is sued or the asset could be lost to a creditor of your co-owner.

That’s one reason why parents with children from a prior marriage should rarely, if ever, own property in Joint Tenancy with a new spouse. Whenever a parent holds property in Joint Tenancy with a spouse, children are effectively disinherited. But upon her death 15 years later in 2013 or later, the entire estate — now worth over $2 million — was subjected to probate. But when the second/last owner dies, the entire estate goes through the often costly, time-consuming and nightmarish probate process. It’s an ownership method so pervasive, many consumers often say they know of no others. Under tenancy in common, when a tenant in common passes away the shares that belong to the dead owner pass to heirs under the laws of Minnesota inheritance.

- At Pulgini & Norton, our real estate lawyers can advise people in Boston and the surrounding cities on the implications of holding property in a joint tenancy.

- The deceased person’s interest was automatically transferred to the other joint tenant.

- Under Missouri statutes, safe deposit boxes may be jointly rented.

- When you own property with a Joint Tenant, each of you owns half of the asset.

- Should one of the owners die, their share in the property automatically transfers to the other joint tenants.

Getting Help from An Estate Planning Lawyer

Through the Unlimited Marital Deduction, the government lets spouses pass assets to one another at death estate tax-free. When Gene died suddenly, Marjorie immediately became the sole owner of their $1.5 million estate by operation of law, circumventing the probate courts. This ownership strategy is widely used by friends, life partners, parents and their children, among others. A tenancy in common is effectively the opposite of joint tenants. However, a joint tenant can be restricted from transferring or selling his or her interest without the consent of the other owner which may lead to disputes. Title can be in one person’s name alone or the asset can be held in joint tenancy, tenancy by the entirety or as tenants in common.

However, joint tenancy is typically only used when neither spouse has children from a prior relationship. However, if the home buyers want to purchase the home as joint tenants, they must specifically state this in writing in order for it to be valid in the state of Minnesota. This is of particular importance when more than one person is going to have an ownership interest in a piece of property. When purchasing a piece of real estate Minnesota home buyers must consider how they want to hold the deed to the property. If you own a piece of property by yourself and leave it to your spouse at your death, your spouse’s tax basis is the market value of the property at the time it’s inherited.

Survivorship Deed

While probate is avoided, joint tenants may not be able to agree on what to do with the real estate. Each homeowner in a joint tenancy gets an equal ownership interest in the real estate. Although joint tenancy has been assailed for years by many estate planning experts, it remains—unfortunately—a very popular form of property ownership. Real estate owned by one or more persons as tenants in common gives a percentage ownership to each person, and upon that owner’s death, their percentage share goes to their estate. However, owning a property as joint tenants gives the remaining partner full legal ownership and control, regardless of whether the deceased left a will. Furthermore, the surviving joint tenant may be subject to gift tax liability if he or she attempts to share the funds in the account with other intended heirs after the original owner’s death.

A very taxing situation occurs, however, when you live in a community property state but hold title to an asset in Joint Tenancy with your spouse. If the sum of all of the survivor’s property is less than the amount that can be passed free of estate tax, this may not be a problem. At the death of the survivor, the value of the entire property is included in the survivor’s estate. As an estate taxation planning device, Joint Tenancy is not optimal.

Tenancy in common is when two or more people own when do you need joint tenancy a property, but not necessarily in the same proportions. This means you must act together as a single entity when making decisions about the property. Joint tenancy is when two or more people own a property equally. In 2011, the Missouri Legislature created a trust specifically for tenancy by the entirety property called a Qualified Spousal Trust. Anyone with a concern or needing help in this area should see their lawyer about a durable power of attorney or place a trusted person on the account as “agent.” Oral understandings about what is to be done with the account balance upon death are frequently misunderstood and often forgotten.

What is a transfer of equity?

Property owned in joint tenancy automatically passes, without probate, to the surviving owner(s) when one owner dies. Among the options we assist you with include structuring ownership of property in a strategic way. Joint tenants have equal rights to rent, control, manage, and possess the real estate. However, if a conveyance is to two non-married people as tenants by the entirety, an estate in joint tenancy is created. For example, if you jointly own a house with a friend, and your friend is a reckless spender, the creditor can sue your friend in court and have the real estate partitioned and sold, even over your objection. The way in which owners hold title can make a difference to whether creditors can attach the property and what happens procedurally in the event of one owner’s death.